High resolution stereo camera 3D gauge

StereoVision SV6000

- Width

- 3D contour: Camber

- 3D contour: Head/tail shape

Presentation

- Field of view up to 10 m

- 2 x high resolution camera 4096 * 2168 pixels at 20 Hz

- Product temperature over 700°C

- Setup & Diagnostic of the gauge with a web browser

- Extended communication features including built in Ethernet and Wifi with Modbus TCP and OPC UA protocols

- Optional industrial network protocols: Profibus DP, Profinet

- On line verification and standardization to maintain high measurement accuracy

- Recording of measures and advanced log features

- Plug-in principle to customize: protocol, External I/O, configuration…

- Simplicity of installation and maintenance, very quick replacement of the gauge

- Laser cross for easy commissionning and verification of accuracy

- Designed for extremely harsh environment: compact water cooled sealed die-cast aluminium housing, heat shield, Air Knife…

Connectivity

StereoVision SV6000 with built in Ethernet connection, integrated digital inputs / outputs and analogue outputs, has a very flexible communication architecture and can easily be connected into any automation system.

The gauge has an integrated Web server and the connection to the gauge with any Web browser from a PC, a tablet gives an access to gauge measurement data and configuration parameters. Remote access is possible for diagnostic assistance.

Application

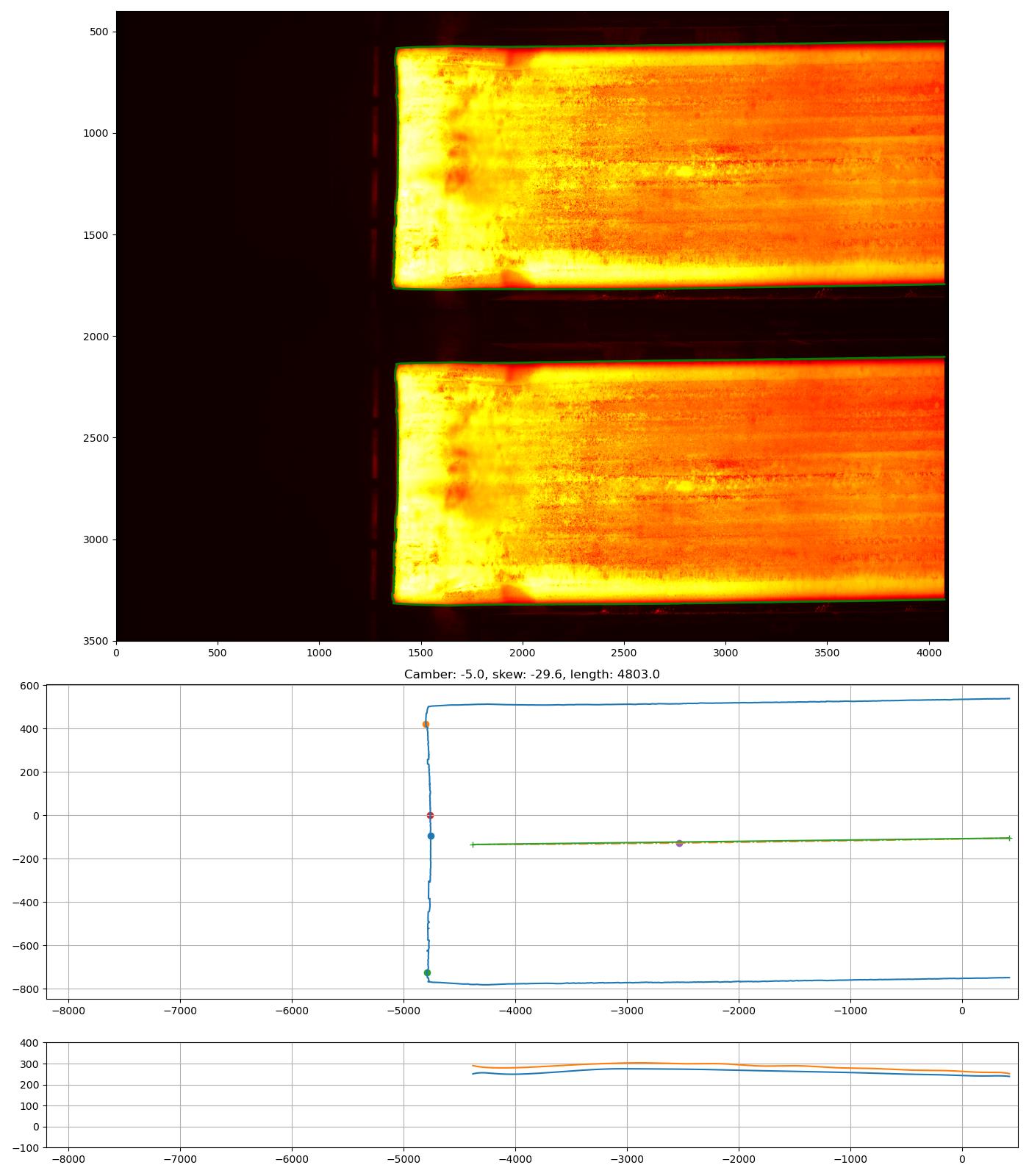

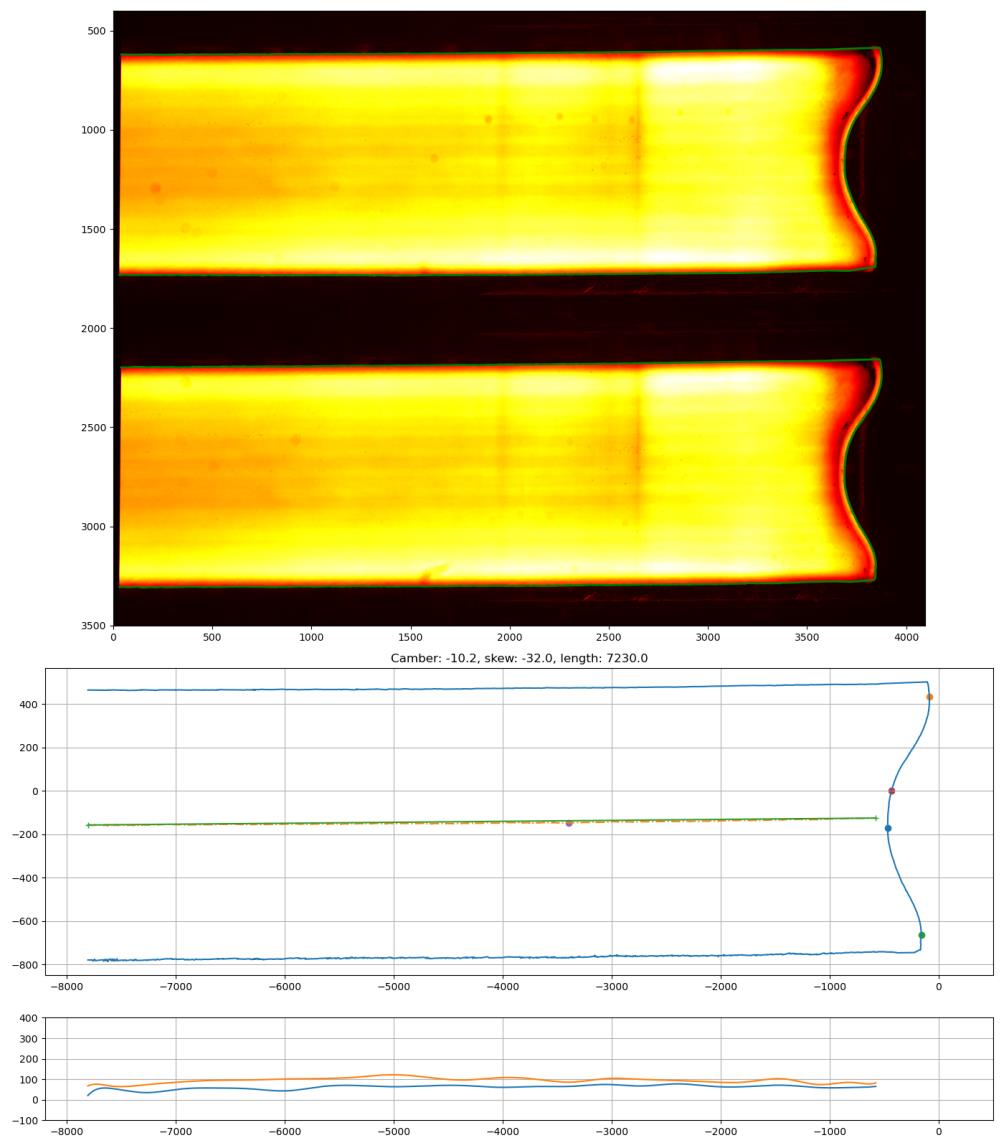

Example: Installation at the exit of a reversing rougher.

Head shapes are displayed at the different passes and tail at the last pass with 3D data.

Typical display: High resolution stereoscopic images with contours and projection of the 3D head and tail points on a length of 8 m.

‹ 返回列表